Revolutionizing Winter Rail Maintenance with IoT

Learn how Embever's IoT integration enables Deutsche Bahn to enhance operational reliability of their locomotives in winter conditions.

Summary

After participating in the DB mindbox 2019 startup cooperation program, Embever collaborates with Deutsche Bahn to ensure electric locomotives remain operational in winter using smart sensors. These locomotives pull passenger trains across Germany and need to stay powered even when idle in winter to avoid delays caused by discharged starter batteries.

Challenge

At the start of the collaboration, Deutsche Bahn faced significant challenges in ensuring the operational readiness of older locomotives during winter. The key challenges were:

Lack of Real-Time Monitoring

Older locomotives lacked systems to notify control centers when they disconnected from the grid, risking battery discharge and operational delays.

Personnel shortage threatens timeliness of trains

Manual checks by skilled train driver personnel, who inspect locomotives every two to six hours, ensure continuous operation but involve night shifts and overtime. When those checks cannot be done it threatens the ability of the train to funciton and the timeliness of train schedules.

Need for Automated Solutions

The lack of required personnel for manual monitoring necessitated the development of an automated solution to ensure the operational of the trains.

Need for a holistic solution

In order to realize future potentials for cost reduction of maintenance tasks, DB looked for a solution that can be easily extended at low cost to monitor many different subsystems of the vehicle.

Solution

In response to these challenges, Embever developed a certified IoT retrofit solution to enhance the performance and reliability of Deutsche Bahn’s locomotives. The approach centers around several key components:

Custom Hardware Integration

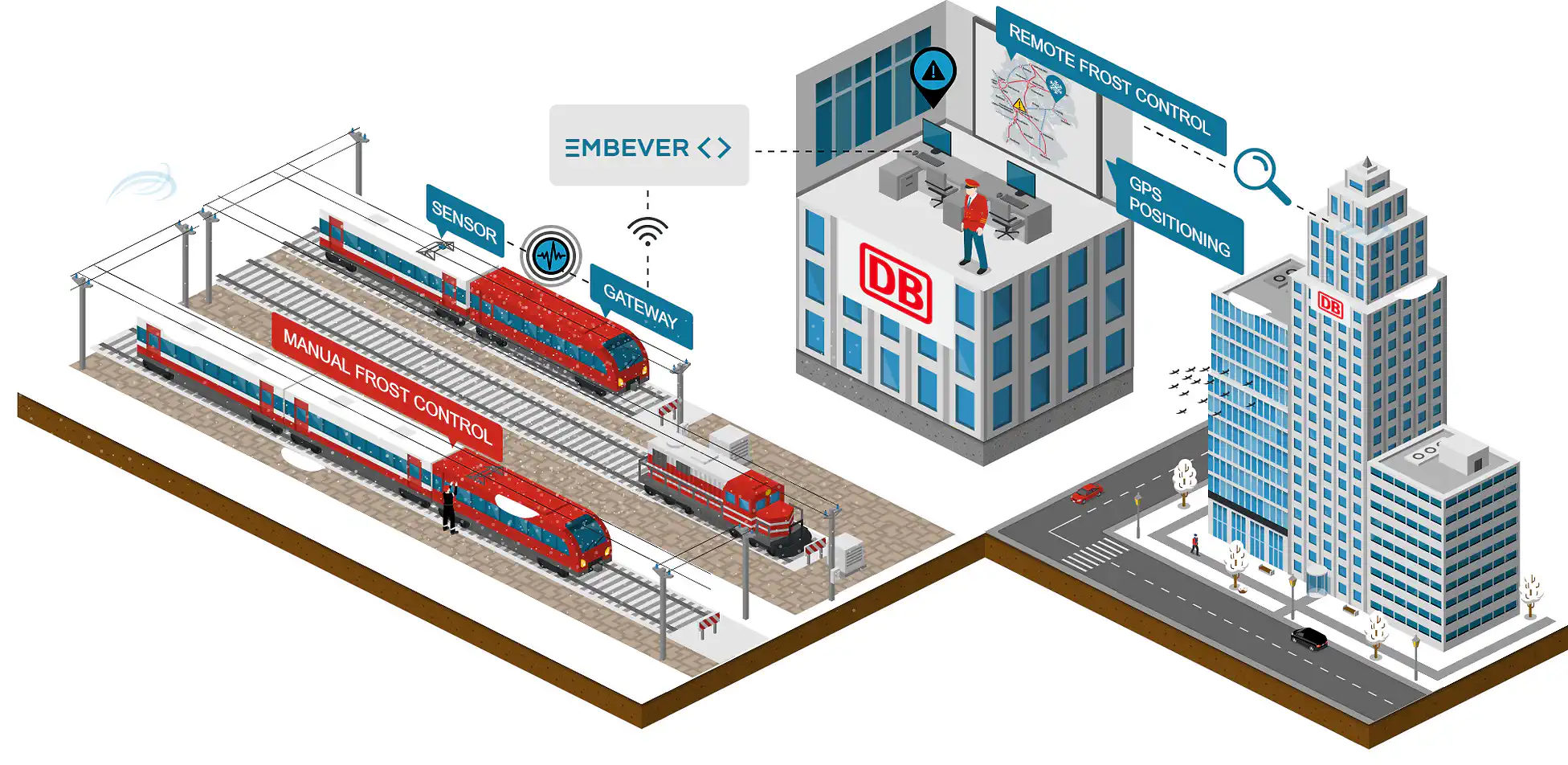

By utilising Embevers expertise of the R&D Hub, a certified and cost effictive retrofit solution for railway vehicles was developed. In the center of the solution is a battery powered gateway that provides a wireless sensor-network on the vehicle. Additional sensors can be added at very low unit and installation cost to monitor many different subsystems of the locomotive.

Wireless, Battery-Powered Sensors

Embever’s smart IoT technology includes wireless, battery-powered sensors that continuously check the voltage of the starter battery and inform the control center directly in case of failures.

Battery-Powered Gateway

A battery-powered gateway using wireless sensors determines whether the locomotive is connected to the power supply and transmits data to an IoT cloud application via mobile radio.

Data Transmission and Dashboard

The gateway sends data directly to the cloud, where the data is then analyzed remotely in the cloud. The information is available to the DB control center, and an incident alert is sent to the technician on duty. Information about the location of the locomotive is also displayed on this dashboard.

Integration with Existing Systems

The integration ensures that the network can be expanded to include any sensors, making the system adaptable and scalable for future needs.

The Outcome

Due to Embever’s IoT integration, Deutsche Bahn can now operate its locomotives far more effectively and reliably in winter. Instead of relying solely on manual checks, maintenance personnel benefit from continuous data collection and real-time transmission, giving them insights into the condition of the starter batteries.

- Proactive Intervention: Issues are identified before they lead to downtime, shortening response times and reducing unexpected outages.

- More Efficient Resource Utilization: With fewer manual inspections required, employees can be deployed exactly where they are needed most.

- Future-Proof System: The battery-powered gateway can be expanded with any number of sensors, allowing additional locomotive systems to be included in the monitoring process.

- Cost Savings: By detecting problems early and optimizing maintenance procedures, costly repairs and failures can be prevented, positively impacting overall operating costs.

This solution demonstrates how existing fleets can be upgraded digitally with cost-effective retrofit systems. The result is not only more economical but also more reliable maintenance processes—an essential step toward greater punctuality and satisfaction in rail transport.

The collaboration between Embever and Deutsche Bahn has led to significant advancements in the maintenance and monitoring of locomotives. By integrating Embever’s IoT platform, Deutsche Bahn can now offer proactive support, minimizing downtime and preventing subsequent damages. This capability enhances the reliability and efficiency of operations, contributing to considerable cost savings for Deutsche Bahn. The system is already in operation, showcasing its effectiveness and potential for broader application.

About DB

Deutsche Bahn is a leading German railway company known for its extensive network and innovative solutions in transportation. Embever, a spin-off of the University of Magdeburg founded in 2017, specializes in hardware, embedded systems, and cloud applications, providing advanced IoT solutions to enhance operational efficiency and reliability in various industries.