Remote Monitoring of Industrial Energy Storage Systems

Discover how Cloud-as-a-Module helps Stercom integrate remote monitoring and maintenance into their industrial energy storage systems.

Summary

Stercom faced the challenge of monitoring the condition and performance of individual battery cells and capacitors in their energy storage systems. The lack of real-time data on these components made it difficult to offer predictive maintenance and proactive service options, potentially leading to downtime and increased operating costs. Embever developed a customized IoT solution that enables Stercom to offer more reliable and efficient energy storage systems.

Challenge

Stercom required detailed insights into the usage, performance, and condition of individual battery cells and capacitors. As the capacity of these cells can diminish over time, it directly impacts the overall performance of the energy storage system. To reduce downtime and operating costs, Stercom aimed to implement a proactive and predictive maintenance approach.

Lack of Insight

After delivery, Stercom’s industrial energy storage systems—including UltraCap storage and battery management systems—do not provide real-time data. This gap made it difficult to deliver additional value to customers through enhanced maintenance and monitoring.

Remote Firmware Updates

With firmware security becoming increasingly important, Stercom’s systems needed to always run the latest firmware and security patches. An over-the-air (OTA) update was identified as a more economical and efficient method compared to manual updates.

Reliable Data Transmission

A stable monitoring and maintenance process required an independent transmission system, separate from the customer network, to avoid disruptions and ensure constant data flow.

Verification of Usage Profiles and Cell Quality

Ensuring the quality and reliability of the supplied cells, as well as adherence to the agreed usage profile, is crucial for minimizing liability risks. Without secure and reliable access to real-time data, this was nearly impossible to achieve.

Opportunity for Proactive Service

The ideal solution would enable continuous, non-invasive monitoring. By identifying potential issues early, Stercom could proactively engage with customers to prevent failures and ensure optimal performance.

Solution

In response to the limited post-delivery insights and the need for proactive maintenance, Stercom developed a tailored IoT solution based on Cloud-as-a-Module to enhance the reliability of their battery management systems. The approach comprises four key components, specifically designed to address Stercom’s challenges:

Custom Hardware Integration

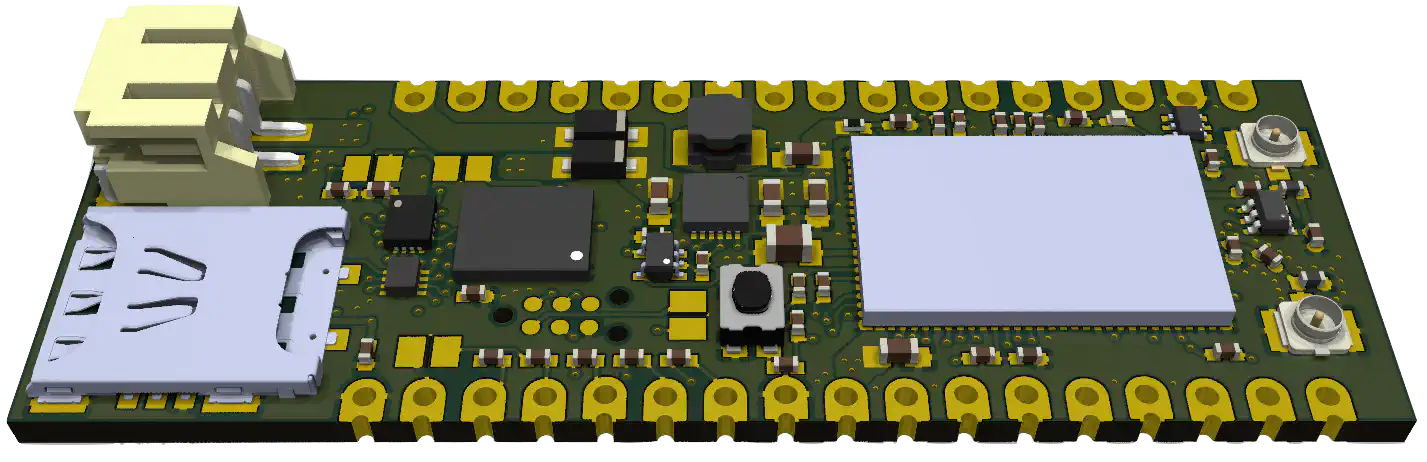

Leveraging Cloud-as-a-Module Mini, Stercom implemented an individual and cost-effective IoT retrofit solution for their existing battery and UltraCap management systems. This allows crucial diagnostic data on key parameters to be captured and transmitted on-site.

Seamless I2C Integration

The IoT functionalities were integrated via the I2C protocol, ensuring effective and efficient communication between the IoT expansion board and the main unit. This method enables real-time data transfer and analysis without impacting core system functions.

FOTA Retrofit

With the help of Embever’s CaaM, Stercom implemented a Firmware-over-the-Air (FOTA) solution via I2C, enabling remote firmware updates. This ensures compliance with the latest security standards and seamless system updates.

Dashboard Implementation

To convert the collected data into actionable insights, Embever deployed a comprehensive dashboard that presents diagnostic information in an intuitive format. Operators and maintenance teams can quickly assess the condition and performance of the energy storage systems and make informed, data-driven decisions.

This all-encompassing IoT solution from Embever meets the need for predictive maintenance and operational transparency, allowing Stercom to offer its users increased reliability, enhanced security, reduced downtime, and lower operating costs.

Outcome

The collaboration between Embever and Stercom has significantly advanced the maintenance and monitoring of energy storage systems. By utilizing Cloud-as-a-Module, Stercom was able to introduce a new predictive maintenance product that enables continuous monitoring of performance and condition data. Additionally, the implementation of a FOTA solution via I2C ensures adherence to the latest cybersecurity standards and smooth updates.

Thanks to these innovations, Stercom can now offer its customers proactive support, reduce downtime, and prevent potential damages early on. The improved reliability and efficiency result in significant cost savings, higher system uptime, and strengthened service offerings, ultimately leading to increased customer satisfaction.

About Stercom

Stercom Power Solutions GmbH is a renowned provider of power electronics for energy storage systems and battery management solutions.