Smart Power Inverter Monitoring

Enabling real-time monitoring and management of industrial power inverter systems through IoT integration.

Summary

The functionality of the auxiliary power converters (APCs) plays a central role in ensuring the operational readiness and availability of railway vehicles. To optimally monitor and maintain these critical systems, ABB relies on Cloud-as-a-Module from Embever. Through real-time monitoring of the APCs, ABB can react early to irregularities – a decisive step towards a more flexible, demand-driven maintenance model instead of fixed maintenance cycles.

Predictive Maintenance Services are intended not only to reduce maintenance costs but also to increase the reliability and service life of the vehicles. Thanks to the low unit costs of Cloud-as-a-Module, state-of-the-art monitoring functions are also feasible on a tight budget.

Challenge

At the beginning of the collaboration, ABB faced the challenge of extending the lifecycle and increasing the added value of the APCs after delivery. Without continuous real-time data on the condition and usage of the devices, it was difficult to offer proactive service – a circumstance that negatively affected both maintenance costs and system availability.

Lack of Post-Delivery Insights

After installation, ABB lacked continuous information about the condition and utilization of the APCs, which limited the long-term added value for customers.

Need for Predictive Maintenance

It was necessary to turn this shortcoming into an opportunity. A solution based on predictive maintenance can minimize downtime and reduce costs.

Potential for Proactive Service

The ideal solution should continuously and non-invasively monitor the APCs so that potential issues can be detected early and addressed proactively – for the benefit of the operators.

Solution

Based on Cloud-as-a-Module, Embever developed a customized IoT solution that specifically addresses the challenges of monitoring the APCs. In addition to the technical implementation, ABB was also supported with consulting services to fully exploit the digital potential of the solution.

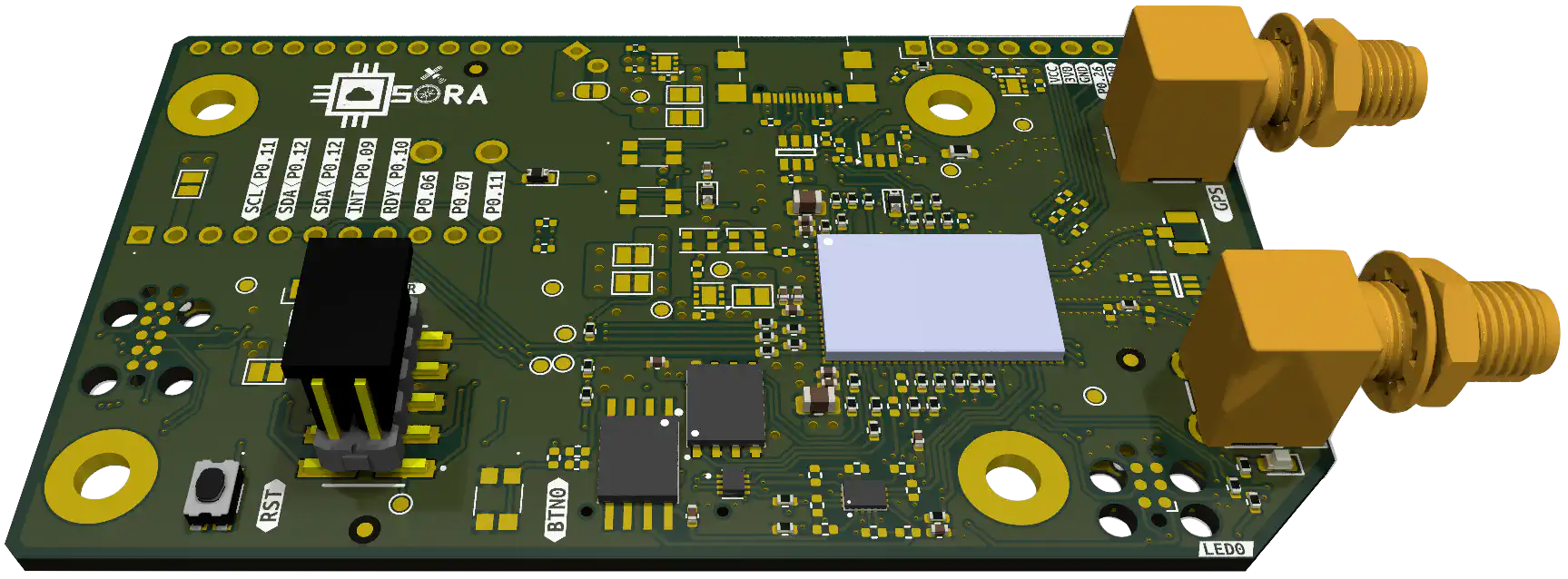

Custom Hardware Integration:

Based on Cloud-as-a-Module Sora, ABB was able to implement a customized, cost-efficient retrofit solution. This solution can optionally be integrated into existing Power Inverter systems to capture and transmit important diagnostic data on site.

Seamless Integration via I2C:

Using the proven I2C interface, the IoT expansion board is seamlessly integrated into the main systems. This allows data to be transmitted and evaluated in real time without disrupting the regular operation of the APCs.

Dashboard Implementation:

To make the collected data immediately usable, a specially tailored dashboard was developed. It presents the diagnostic data clearly, enabling operators and maintenance teams to quickly assess the condition and performance of the APCs and make data-driven decisions.

Integration with ABB Ability™:

The entire solution is integrated with ABB Ability™ – ABB’s cross-industry digital offering. This integration enables the use of advanced analytics and predictive maintenance functions while ensuring that real-time data is transmitted to various predictive maintenance systems.

Outcome

The collaboration between Embever and ABB has led to significant improvements in the maintenance and monitoring of auxiliary power inverters. By utilizing Cloud-as-a-Module, ABB was able to introduce a new predictive maintenance product for its customers (configuration option Predictive Maintenance and IoT) with low initial investment and low per-unit costs. Existing devices can be retrofitted. This innovation enables ABB to continuously monitor the performance of its power inverters, allowing experts to detect potential issues before they escalate.

As a result, ABB can now provide proactive support, minimize downtime, and prevent collateral damage. This capability not only improves the reliability and efficiency of operations but also contributes to significant cost savings for its customers, particularly after the warranty period expires. By reducing service costs and improving uptime, ABB has strengthened its service offerings and achieved a remarkable improvement in customer satisfaction.

The system is already in use on trams in Zurich and Vienna, demonstrating its effectiveness and potential for broader application.

About ABB

ABB is a globally recognized market leader in the fields of electrification and automation with a history spanning over 140 years. The company offers a wide range of products, systems, solutions, and services across various sectors, including utilities, industry, transport, and infrastructure. ABB is particularly known for its innovations in robotics, industrial automation, and electrification products, which have significantly enhanced industrial productivity and energy efficiency. Its APCs set new benchmarks for efficient power supply in railway vehicles worldwide.